Home > Company Introduction

Company Overview

Shenzhen Qinhouji Plastic Chemical Co., Ltd. specializes in the R&D, production and sales of new polymer functional additives. Committed to the research and development and innovation of laser marking lead carving additives, plastic additives and masterbatches, to solve the pain points of the industry and always take quality as the core value of the enterprise. The company has passed the IS09001 international quality management system certification, and its products meet the EU environmental protection (ROHS, REACH) standards. The company pays attention to the quality inspection of the product production process, has an independent laboratory and R & D center, and is equipped with large continuous mixing granulator, twin-screw extruder , high and low temperature internal mixer and low-speed mixer, kneader, crusher, injection molding machine, computer color measuring instrument, test chamber, fiber laser machine, purple laser machine and other machinery and equipment to ensure that products meet customer requirements and quality creates value.

-

Trading CompanyBusiness Type

-

2014Year Established

-

5,000-10,000 square metersFactory Size

-

11 - 50 PeopleTotal Employees

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

11 - 50 People Total Employees

-

5-10 People Quality Inspectors

-

ISO9001 Product Certifications

-

North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, Domestic Market Main Markets

-

shenzhen Port of Shipment

-

Polymer & Resin Main Industry

-

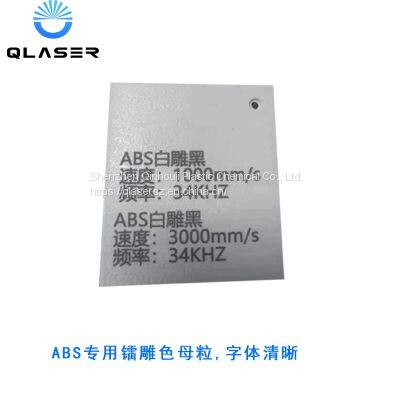

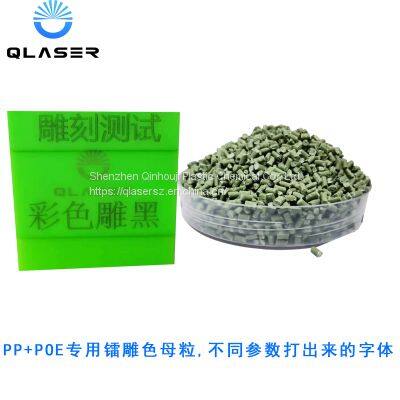

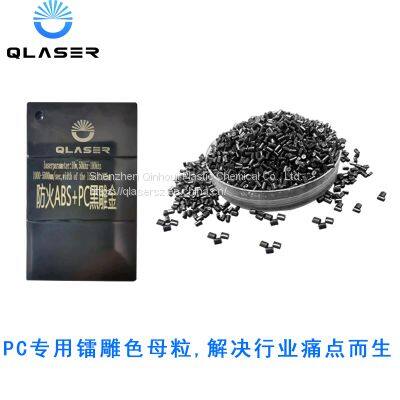

Our ServicesLaser engraving masterbatch is also called laser engraving masterbatch. Laser marking is also highly efficient and environmentally friendly. Traditional marking methods usually require the use of chemical dyes or corrosives, while laser marking is directly applied to the surface by a laser beam without adding any chemicals. This not only saves a lot of manpower and material resources, but also reduces environmental pollution. At the same time, laser marking is fast and can be operated automatically, which improves production efficiency and marking consistency. Laser marking is an efficient and sustainable option for mass production factories and businesses. In addition, laser marking can also operate on a variety of materials. Whether it's metal, plastic, ceramic or glass, laser marking achieves the desired effect. This versatility makes laser marking ideal for many industries such as electronics, automotive, medical, and more. Through laser marking, these industries can mark product information on different materials, improving product recognition and management efficiency. Overall, laser marking plays an important role in everyday life. Not only does it make quality control easier, it also offers the possibility to add a lot of information to tiny surfaces. Laser marking has many advantages such as high precision, durability, anti-counterfeiting, high efficiency, environmental protection and versatility, making it a preferred marking method in many industries. With the continuous development of technology, it is believed that laser marking will show its unlimited potential in more fields. The effect of ABS laser engraving masterbatch white engraving and black is very ideal, which greatly exerts the advantages of the industry, reduces the cost of silk screen printing, is environmentally friendly, and improves production efficiency.

Our ServicesLaser engraving masterbatch is also called laser engraving masterbatch. Laser marking is also highly efficient and environmentally friendly. Traditional marking methods usually require the use of chemical dyes or corrosives, while laser marking is directly applied to the surface by a laser beam without adding any chemicals. This not only saves a lot of manpower and material resources, but also reduces environmental pollution. At the same time, laser marking is fast and can be operated automatically, which improves production efficiency and marking consistency. Laser marking is an efficient and sustainable option for mass production factories and businesses. In addition, laser marking can also operate on a variety of materials. Whether it's metal, plastic, ceramic or glass, laser marking achieves the desired effect. This versatility makes laser marking ideal for many industries such as electronics, automotive, medical, and more. Through laser marking, these industries can mark product information on different materials, improving product recognition and management efficiency. Overall, laser marking plays an important role in everyday life. Not only does it make quality control easier, it also offers the possibility to add a lot of information to tiny surfaces. Laser marking has many advantages such as high precision, durability, anti-counterfeiting, high efficiency, environmental protection and versatility, making it a preferred marking method in many industries. With the continuous development of technology, it is believed that laser marking will show its unlimited potential in more fields. The effect of ABS laser engraving masterbatch white engraving and black is very ideal, which greatly exerts the advantages of the industry, reduces the cost of silk screen printing, is environmentally friendly, and improves production efficiency.